Clark Warehouse Forklifts Anaheim

Forklift Safety Rules and Suggestions

In the United States, 20,000 people are hurt each year in accidents connected to the use of forklifts. And each year around 100 deaths are attributed to forklift accidents. Luckily, correct training regarding operation procedures and maintenance could considerably reduce the risk of accidents. The following basic safety rules and suggestions should be followed when utilizing a forklift.

Training

The employer is responsible for making certain that workers are trained to operate a forklift and have gone through a proper training program. Training involves a combination of presentations, lectures, practical hands-on training and discussions. Reevaluation must occur every three years. Forklift operators must be up-to-date with current forklift safety regulations. Forklift training program content covers dangers of forklift operations, general workplace hazards, dangers related to using the particular forklift which the employee will be utilizing and workplace surfaces and lighting. An employee should be at least 18 years old to utilize a forklift.

Maintenance

In order to make sure that the equipment is working safely and properly, forklift inspection should be done each day. The inspection includes keeping a checklist of items and reporting any problems at once.

The Work Site

Safe use of a forklift involves a clean and safe workplace. A safe work site means establishing "traffic lanes" that are just designated for forklift use. Warning systems like flashing lights and horns must be in place to indicate when there is a forklift approaching. Forklift docking stations must be inspected on a daily basis and kept in good repair.

General Guidelines

General safety rules for forklift use comprise ; respecting the forklift load capacity and never exceeding the maximum; ensuring there is enough clearance for the load; lowering or raising the load only while the forklift is stationary; and keeping legs, hands and arms in the vehicle during operation.

- Yale Stand Up Forklift Anaheim

A forklift to be a successful model should be built powerful to last the working conditions for many hours of use. It has to be able to move loads effectively and quickly too. The machinery... More - Toyota Dual Fuel Forklift Anaheim

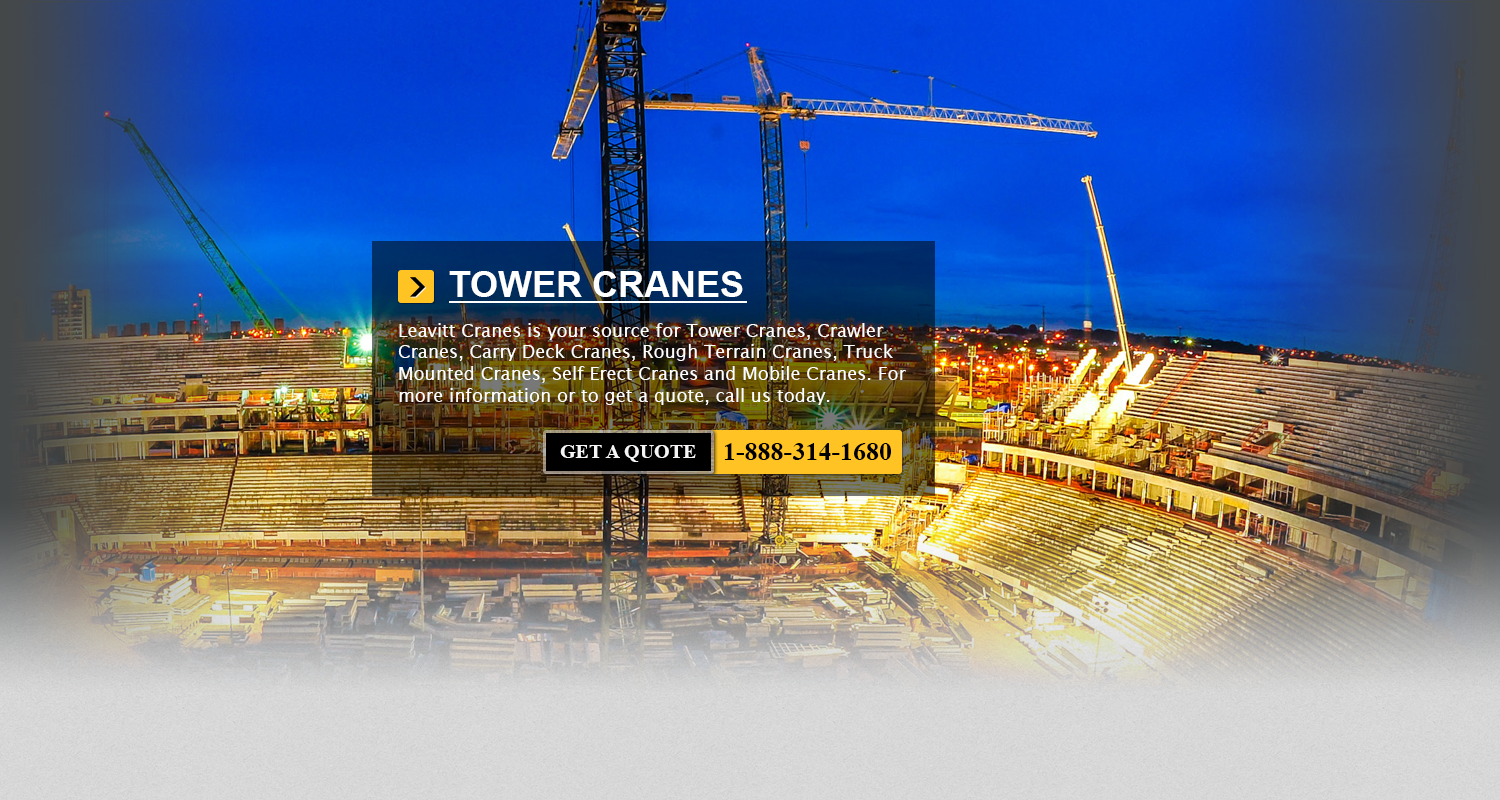

Sakichi Toyoda was the first founder of the Toyota Industries Corporation or TICO during the year 1926. TICO has expanded the scope of its business domains since the companies inception to promote diversification, like logistic... More - Comansa Tower Cranes Anaheim

Since 2011, the Linden Comansa company has offered its clients the LC 1600 series tower cranes. This series includes the models: 16 LC 185, 16 LC 260 and 16 LC 220. These units are available... More - Yale Outdoor Forklift Anaheim

Reach Assembly & Carriage Both the carriage and the reach assembly receive lots of stress throughout a typical work shift. In order to make sure that the truck keeps production levels high, high durability of... More - Mitsubishi IC Forklifts Anaheim

The forklift usage all around the world has grown in insurmountable measures in regards to the warehousing and manufacturing industries. A forklift is a powered industrial truck utilized for lifting and transporting items. The equipment... More