Potain Self Erect Cranes Anaheim

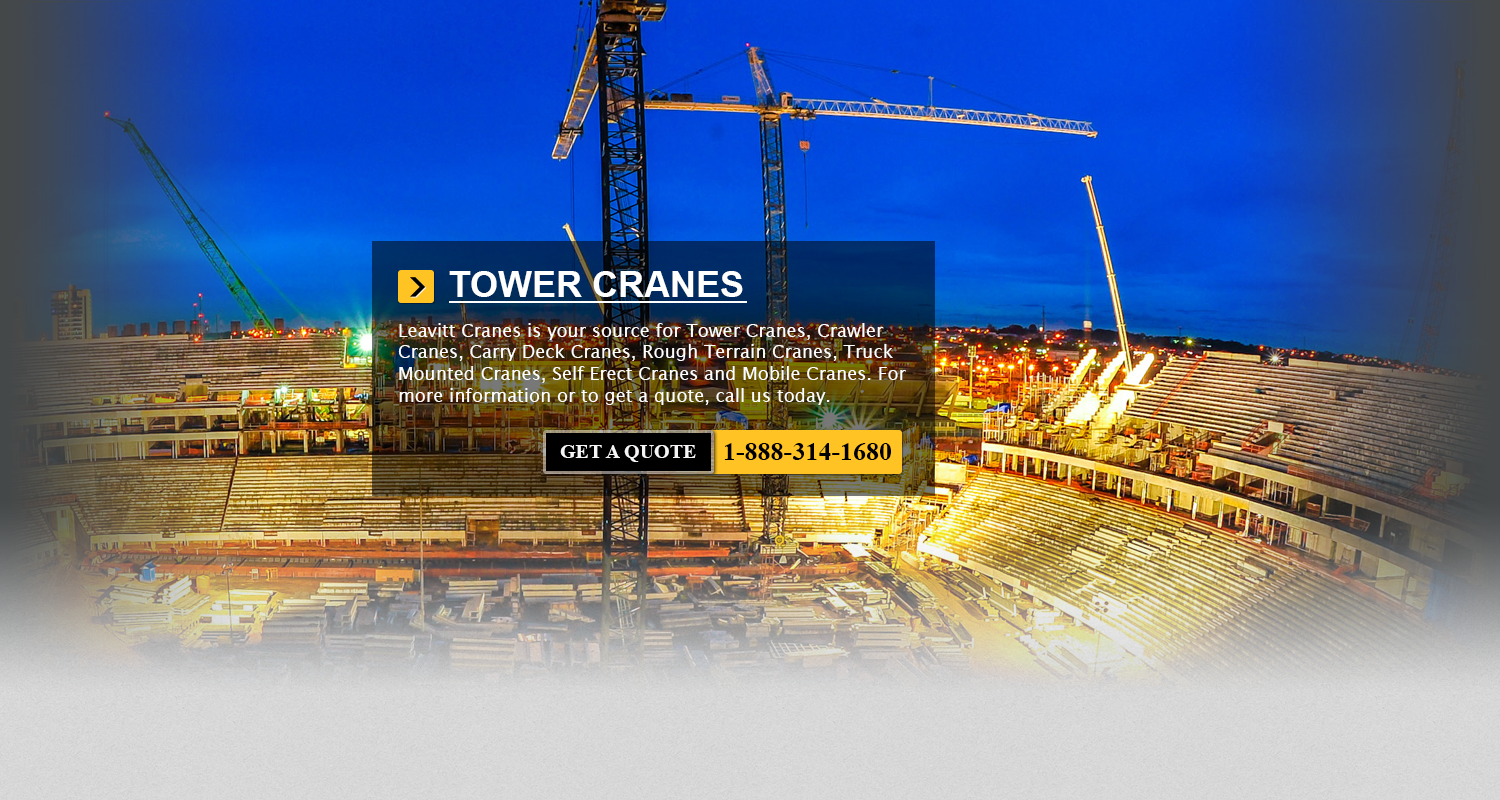

For huge building construction projects, tower cranes are used quite often. These machines are quite essential for heavy lifting as well as positioning materials and equipment. Tower cranes provide a unique configuration that offers many advantages over more traditional cranes. These advantages consist of: quiet electrical operation, higher vertical lift, increased capacities, and reduced space requirements.

Hammerhead Crane

The hammerhead crane is usually associated with a tower crane. The long horizontal jib is connected to a vertical tower, in this situation. One end of the jib acts as a counterweight and the other end of the jib extends horizontally over the worksite. On the hammerhead crane, there is a trolley. This trolley holds the lifting cable and can travel along the length of the jib. The tower crane is capable of operating anywhere within the jib's radius.

Self-Erecting Tower Cranes

A self-erecting crane is capable of completely assembling itself at the jobsite without any help from a secondary crane. This greatly saves time in equipment costs and provides a huge advantage in setup time too. Self-erecting cranes are normally remote-controlled from the ground, though there are several models that have an operator cab built onto the jib.

Self-erecting cranes are normally freestanding and this allows them the opportunity to be able to be moved around. There are several models which have a telescoping tower that enables the crane to work at multiple heights without the need to reconfigure the tower.

Luffing Jib Tower Crane

Usually, in urban work environments, there is not enough clearance or space for the jib to rotate freely without being blocked by existing buildings. A luffing jib tower crane is great for such tight spaces. The majority of tower cranes have a fixed horizontal jib. The driver could lower or raise a luffing jib in order to allow the crane to swing in a reduced radius.

- Yale Stand Up Forklift Anaheim

A forklift to be a successful model should be built powerful to last the working conditions for many hours of use. It has to be able to move loads effectively and quickly too. The machinery... More - Toyota Dual Fuel Forklift Anaheim

Sakichi Toyoda was the first founder of the Toyota Industries Corporation or TICO during the year 1926. TICO has expanded the scope of its business domains since the companies inception to promote diversification, like logistic... More - Comansa Tower Cranes Anaheim

Since 2011, the Linden Comansa company has offered its clients the LC 1600 series tower cranes. This series includes the models: 16 LC 185, 16 LC 260 and 16 LC 220. These units are available... More - Yale Outdoor Forklift Anaheim

Reach Assembly & Carriage Both the carriage and the reach assembly receive lots of stress throughout a typical work shift. In order to make sure that the truck keeps production levels high, high durability of... More - Mitsubishi IC Forklifts Anaheim

The forklift usage all around the world has grown in insurmountable measures in regards to the warehousing and manufacturing industries. A forklift is a powered industrial truck utilized for lifting and transporting items. The equipment... More