Doosan Lifts Trucks Anaheim

Ever since Doosan Infracore began producing diesel engines during the year 1958, the company has continued to manufacture its R&D capacities to stay at the forefront of the business in Korea. During the year 1975, Doosan started mass producing diesel engines at its first large-scale plant. Within 10 years the company's production technology had advanced to the point that making its very own diesel engine model was possible. Doosan's leadership position in the business was secured. In the year 1995 Doosan made its first low-emission diesel engine, followed by commercial vehicle CNG engines three years later. Ever since 2000, the company has developed technology for sophisticated common-rail engines, Tier 3-compliant engines and low-pressure natural gas engines. In order to follow stringent Euro emission control standards, the company developed a heavy-duty, low emission diesel engine model during 2007.

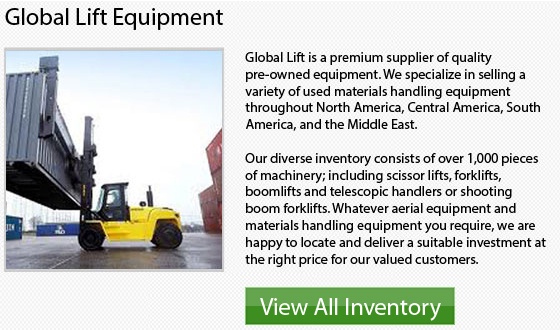

Doosan has many facilities throughout the globe that help make 60 different types of engines, as well as materials and parts. Products consist of diesel engines and natural gas engines for trucks, forklifts, buses, construction equipment, generators, ships and more. Engines vary from 70 to 1,500 horse power. Annual output is presently 75,000 units.

The company is continually engaged in expanding R&D capabilities to increase output and expand to more markets. Demand for stricter regulations governing engine emissions has led the company to build a compressed natural gas engine factory in the US in the year 2008, and a joint venture factory in Xuzhou, China. The plant in China could make 50,000 diesel engines on a yearly basis, with production scheduled to start in 2011.

- Yale Stand Up Forklift Anaheim

A forklift to be a successful model should be built powerful to last the working conditions for many hours of use. It has to be able to move loads effectively and quickly too. The machinery... More - Toyota Dual Fuel Forklift Anaheim

Sakichi Toyoda was the first founder of the Toyota Industries Corporation or TICO during the year 1926. TICO has expanded the scope of its business domains since the companies inception to promote diversification, like logistic... More - Comansa Tower Cranes Anaheim

Since 2011, the Linden Comansa company has offered its clients the LC 1600 series tower cranes. This series includes the models: 16 LC 185, 16 LC 260 and 16 LC 220. These units are available... More - Yale Outdoor Forklift Anaheim

Reach Assembly & Carriage Both the carriage and the reach assembly receive lots of stress throughout a typical work shift. In order to make sure that the truck keeps production levels high, high durability of... More - Mitsubishi IC Forklifts Anaheim

The forklift usage all around the world has grown in insurmountable measures in regards to the warehousing and manufacturing industries. A forklift is a powered industrial truck utilized for lifting and transporting items. The equipment... More