Nissan Counterbalance Forklifts Anaheim

The counterbalanced forklift is a lift truck which utilizes a counter balance that is connected to the back end of the equipment. This counterbalance effectively balances loads that are placed on the forks at the front end of the equipment. This design is engineered to stabilize conventional forklifts. As far as electric counterbalance forklifts are concerned, the counterweight is formed by the battery itself.

Nearly every lift truck manufacturer would have in their product range, a counterbalance forklift. These machinery would come in a wide assortment of fuel sources, sizes and configurations. These lift trucks could be equipped. They are capable of working in diverse applications. These lift trucks are equipped with a variety of accessories. Common attachments and options include: slip sheet attachments, fork shifts, hydraulic clamps and side shifts just to mention a few.

The counterbalance forklift has in fact revolutionized the entire industry of material handling. These machinery are vital to the shipping and receiving centers around the globe since they are used for loading, stacking, unloading and horizontal transport functions. The standard warehouse lift trucks are normally utilized for lift heights less than 6 meters or 20 feet. There have been some units recently developed which are capable of lifting to heights 9.5 meters or 31 feet. The smaller 1-1.8 ton or 4000 pound forklifts are the main workhorses in most warehouses. These are the most common models which most small companies will own. The average warehouse counterbalance forklift is really a wide-aisle truck that needs approximately 11 feet or 3 meters to turn in.

Counterbalance forklifts are not necessarily confined to the warehouse. They are usually used for container carrying and heavy use together with pretty much every use in between. Counterbalance lift trucks are the most versatile and widely utilized of all materials handling equipment.

Due to their durability and versatility, counterbalance lift trucks are commonplace in a huge array of working environments, like warehousing, production and retail. Some of the industrial use consist of: automotive, timber, food and chemical industries.

- Yale Stand Up Forklift Anaheim

A forklift to be a successful model should be built powerful to last the working conditions for many hours of use. It has to be able to move loads effectively and quickly too. The machinery... More - Toyota Dual Fuel Forklift Anaheim

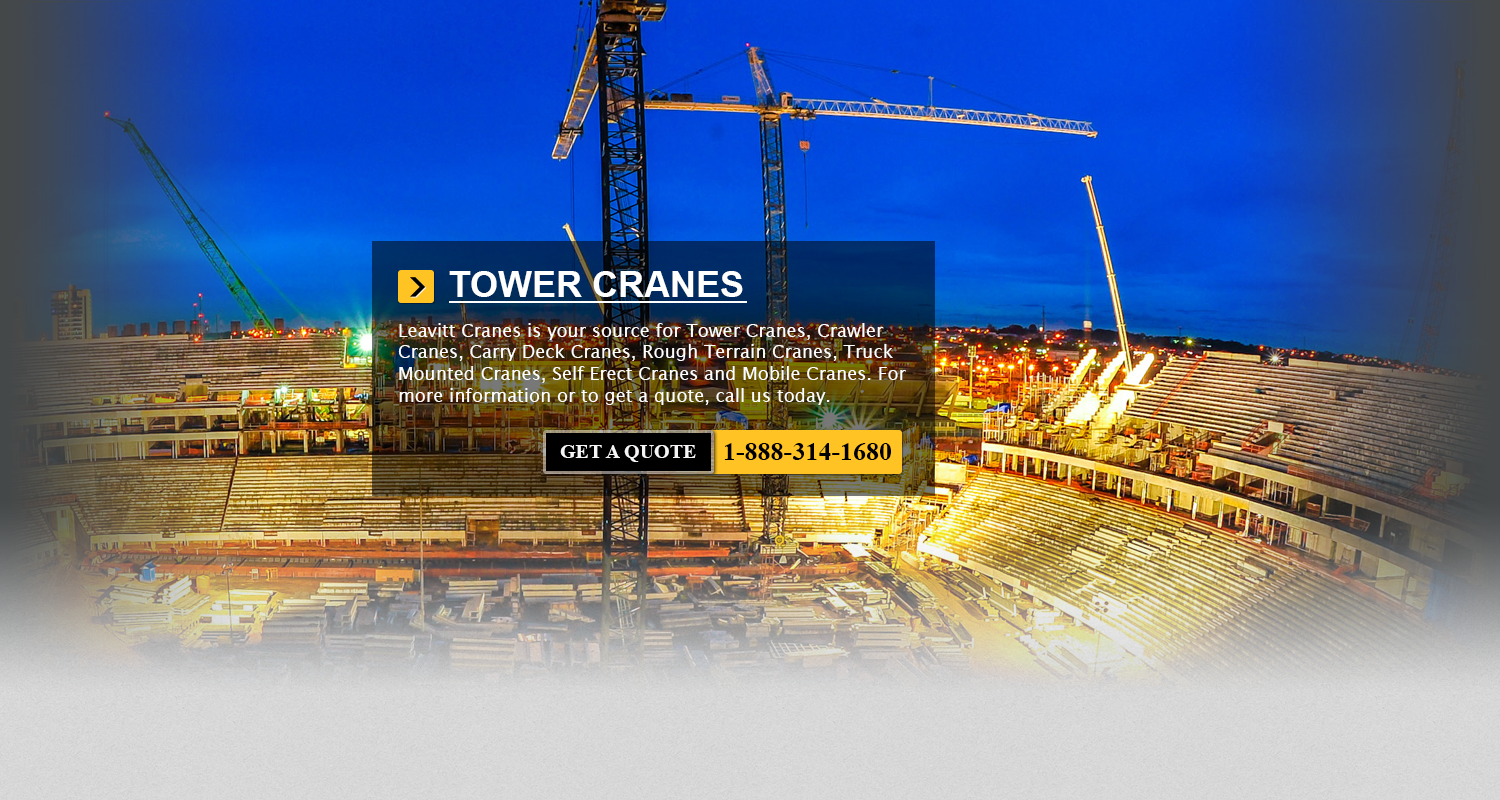

Sakichi Toyoda was the first founder of the Toyota Industries Corporation or TICO during the year 1926. TICO has expanded the scope of its business domains since the companies inception to promote diversification, like logistic... More - Comansa Tower Cranes Anaheim

Since 2011, the Linden Comansa company has offered its clients the LC 1600 series tower cranes. This series includes the models: 16 LC 185, 16 LC 260 and 16 LC 220. These units are available... More - Yale Outdoor Forklift Anaheim

Reach Assembly & Carriage Both the carriage and the reach assembly receive lots of stress throughout a typical work shift. In order to make sure that the truck keeps production levels high, high durability of... More - Mitsubishi IC Forklifts Anaheim

The forklift usage all around the world has grown in insurmountable measures in regards to the warehousing and manufacturing industries. A forklift is a powered industrial truck utilized for lifting and transporting items. The equipment... More