Caterpillar Lift Trucks Anaheim

How to lessen the cost of damage to fork lift trucks

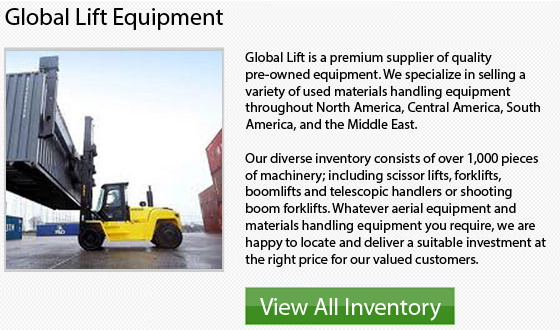

There are several common reasons for forklift truck damage, no matter what the workplace may be. Instances of damage could be very expensive. Costs normally relate to costs of staff downtime and repair. Luckily, nearly all kinds of forklift truck damage are preventable. By following these simple tips, fleet operators can ensure that repair expenses and downtime are minimized or prevented.

Check that the machine is appropriate for the job and the surroundings. Carry out safety checks on truck parts and important systems. Be certain that operators of forklifts are well trained and that supervision is provided. Examine the layout of the operating area/warehouse to make certain it facilitates movement. Develop a repair/maintenance plan that could guide actions when anything goes wrong.

Even if the working environment is mostly the cause of accidents, fault could be sometimes be the actions of the drivers. A safe working surrounding involves having the right equipment for the application.

The most cost-effective approach is to take a long-term and coordinated view of fleet management. The instances of damage can be reduced greatly by having the very same company which supplied the trucks carry our maintenance and repairs and train the drivers. The company can also offer recommendation regarding the warehouse design.

- Caterpillar Narrow Aisle Forklifts Anaheim

Narrow Aisle Forklift Utilized to both lower and lift loaded pallets from storage spaces that are high is a narrow aisle forklift. This type is recommended for work environments with narrow spaces between aisles, such... More - Komatsu Dual Fuel Forklifts Anaheim

Dual Fuel Engine DF or Duel Fuel Engines are the kind of engines that can work on a mixture of diesel fuel and gas fuel or it can work on diesel fuel alone. Duel Fuel... More - Terex Empty Container Handlers Anaheim

Low operating expenses and great efficiency are some of important features on Fantuzzi's empty container handlers. Fantuzzi began producing their very first empty container handler during the year 1974. Ever since they began, Fantuzzi has... More - Yale Outdoor Forklift Anaheim

Reach Assembly & Carriage Both the carriage and the reach assembly receive lots of stress throughout a typical work shift. In order to make sure that the truck keeps production levels high, high durability of... More - Haulotte Articulating Man Lifts Anaheim

Kinds of Articulating Man Lifts Man lifts are offered in a variety of electric powered and engine powered models, depending upon the function and the industry. These dependable machinery can be utilized for a variety... More